Table of Contents

In this series of articles, NIZO Food Research Division Manager and FoodNavigator advisory panel member René Floris discusses some of the big issues in today’s food industry.

When consumers shop for food, food safety is rarely at the top of their mind, because they see it as a ‘given’. Clearly, all food on the market must be safe and it is up to producers to ensure this. But the risk of contamination runs through the entire food production chain: from raw materials and ingredients, to formulation and processing, and on to the finished product. Some microbial contaminants are pathogenic and cause foodborne infection. Others produce toxins in foods – which can be just as dangerous.

As a food manufacturer, preventing outbreaks of food-borne illness is key: a health issue linked to your product can have serious repercussions for your company, your reputation and your brand. Marjon Wells-Bennik, NIZO’s Principal Scientist Food Safety, with over 20 years academic and industrial experience in food safety and microbiology, explains the dangers of bacterial toxins in food, and what food producers can do to minimise the risks.

René Floris: Where do bacterial toxins come from, and how do they get into food?

Marjon Wells-Bennik: Toxins can be released by certain bacteria at any point in the food production chain if conditions allow for their growth. The most well-known bacteria responsible for foodborne intoxications are Staphylococcus aureus, Bacillus cereus, and dangerous Clostridium botulinum. Staphylococcus is found on skin and can contaminate foods during handling, while Clostridium and Bacillus are found in soil and water, for instance, and can be present in ingredients.

What food producers must keep in mind is that toxins produced in the food can cause illness, so a person doesn’t have to ingest high levels of live bacteria to get sick. In the case of Clostridium, ingestion of minute amounts of toxin will already lead to severe illness, even if the levels of bacterium in the product are low. And in the cases of Bacillus and Staphylococcus, the toxins are highly stable – including under conditions that kill off the bacteria. So even if bacteria are undetectable but had an opportunity to release toxin, the health risk is there.

RF: What are spore-forming bacteria, and why is this important for food manufacturers?

MW-B: Some bacteria exist only in a ‘vegetative’ state. This means they are normal, actively growing cells that cannot survive harsh conditions, such as heat treatment.

But other bacteria form dormant spores, which are very hardy. They may be resistant to heat, acidification, etc. Under the ‘right’ conditions, these spores germinate to become metabolically active again.

Toxin-producing bacteria may or may not be spore formers: Staphylococcus aureus isn’t, for example, while both Clostridium botulinum and Bacillus cereus are. The spores can be very hard to get rid of during food production. However, if they survive processing and germinate in foods, controlling the conditions that prevent outgrowth can prevent production of toxins.

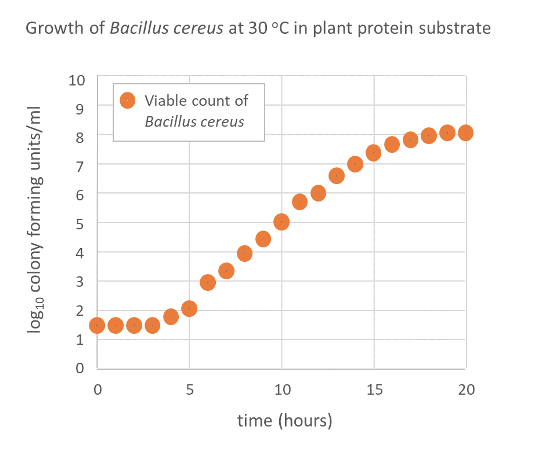

Figure 1: Toxin producing Bacillus cereus grows fast in plant protein liquids

RF: How do we prevent food poisoning from toxins?

MW-B: There are several conditions that are necessary for food intoxication to occur. The bacteria or toxins must be present in the food, the conditions must support the growth of the bacteria, the bacteria need enough time in the favourable conditions to grow and produce the toxin, and finally, the food must be eaten.

To prevent the risk of food-borne illness, you therefore need to eliminate one of these conditions. So you firstly make sure that toxins cannot be produced during the processing of your product, and secondly that the product will not support the outgrowth of a toxin-producing bacterial strain.

Generally, controlling your manufacturing process ensures that a safe product comes off the line. Staphylococcus aureus for example, is easily inactivated by heat and does not grow at low temperatures. Contamination of finished product is relatively easy to prevent with standard hygiene measures in the production plant.

Spore formers are much more difficult to get rid of in the production line, so you need to make sure they cannot germinate and produce toxins during food manufacturing or in the product once it leaves your facility. To prevent outgrowth, you must ensure that you have the right preservation systems in place, that the food is kept at the right temperature, etc.

RF: What challenges increase the risk of toxin contamination in food?

MW-B: To start with, perhaps your sourced ingredients arrive with a higher number of bacteria than your processes can handle, or are contaminated with a very resistant strain. This is a particular risk with the increased use of plant proteins, which bring in a wider and less familiar variety of bacteria, especially spore formers, than more traditional protein ingredients.

Furthermore, when you are developing a new product or modifying an existing food, new risks can creep in. If you are changing an ingredient, using milder processing, or reducing preservatives such as salt, sugar, etc., you may be creating an opportunity for bacteria to survive, grow and release toxins.

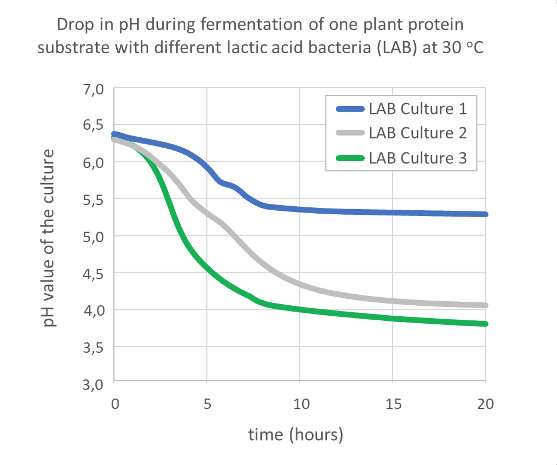

Take the example of replacing acidification of a product with fermentation. Fermentation is increasingly popular for plant-based proteins, because it can solve issues with flavour, texture, spoilage, etc. But some fermentation strains are slower to acidify than others. If your culture acidifies too slowly, bacterial contaminants may have the time to grow and produce toxins before the pH reaches a level that kills them. If you then test for the presence of bacteria, you may not find any trace. But the toxins are still there, so the product is not safe.

Figure 2: Some lactic acid bacteria do not acidify fast and not enough in plant substrates.

RF What sorts of tests and models can be used to ensure a product is safe from toxins?

MW-B: There are two different approaches, depending on the circumstances.

If a contamination has occurred, you need to react. Firstly, you can test not only for the presence of bacteria, but for toxins such as the highly heat-resistant cereulide, lichenysin and surfactin. Then you need to determine the cause of the problem, in order to find a solution. Is the toxin-producing ingredient coming in with your ingredients, or being introduced in your production line, for example?

Identifying the specific strain of bacteria can help. If it isn’t a super heat-resistant strain that could survive your processing, contamination had to occur after your heat treatment. That allows you to focus your efforts on your production line. On the other hand, if it is a spore former that managed to survive heat treatments, there are different ways you may need to react.

The other situation is when you are making something new or changing something in your product or process. You can include toxin safety at every stage of the design of your product. Microbial predictive models can evaluate the risk of survival, growth and toxin production of bacteria during manufacturing and throughout your product’s shelf life. This can include tests with real bacterial strains, to see how they perform under real-life storage or processing conditions. In the case of toxin-producers, this isn’t only outgrowth, but determining if the bacteria have an opportunity to release dangerous amounts of toxins.

There is an enormous diversity of bacteria and bacterial strains, and in the behaviours of these living microorganisms. This makes food safety a complex challenge for food producers, going far beyond checking for the presence of common pathogens or spoilers. But with a greater understanding of the bacteria and the risks they create, you can take specific actions to ensure a safe food chain for consumers.

Related cases

Related blogs

- Lichenysin

- Cereulide

- Antimicrobials

- Virulence

Related terms

© NIZO 2025 | Sitemap - Privacy Statement - Cookie Statement - Terms & Conditions

Website by: Online Marketing Agency