Table of Contents

In this series of articles, NIZO Food Research Division Manager and FoodNavigator advisory panel member René Floris discusses some of the big issues in today’s food industry.

Fouling can be responsible for 10 to 20% of food production costs, as well as more than 50% of the carbon footprint. Hans Tromp, Senior Scientist at NIZO, explains some of the challenges of minimising the impact of fouling, and how an industry consortium on proteins on steel is combining practical and scientific approaches to help food manufacturers find real solutions.

RF: What are the challenges food manufacturers face in eliminating fouling?

HT: Fouling in food processing is a well-known problem that can result in increased down-time, reduced production capacity and greater product loss. Over time, the industry has adopted very well-established approaches for minimising and handling fouling. These range from careful equipment design that eliminates “stagnation points”, to regular cleaning of the equipment. However, the cleaning in particular involves stopping the production run, and using large amounts of water and chemicals to remove the deposits. The dirty water and the chemicals then need to be disposed of. Depending on the facility, production might be shut down every 6 to 12 hours to clean out the equipment. This adds more costs to production, while reducing productivity and efficiency.

These approaches have evolved through long-time experience, and generally they do work. However, because they are based solely on rather conservative trial-and-error, there is room for improvement. If we know more about how and why fouling is occurring in a specific food production process rather than a more general level, we can find ways to slow or even prevent certain types of fouling. Imagine, for example, that a facility currently cleaning every 6 hours can extend its production runs to 7 hours between cleanings. Even this seemingly small improvement would drastically increase production, and reduce the use of water and chemicals.

We need to get more insight into fouling, and fill in the knowledge gaps. A NIZO-led industrial consortium is working to better understand the real-life sequence of events that leads to fouling, and to uncover optimised approaches to cleaning.

RF: How can production facilities optimise their approach to fouling?

HT: Fouling is actually a very complex process, and there are a lot of elements that can contribute to it. For example, the steel surface and coating of the processing equipment’s inner surface, the mineral content of the water, the heating temperature, the flow rate, the content of the product itself, etc. So a whey-based product will show different fouling behaviour than a casein product, or calcium-rich water may provoke more mineral fouling than a purified water. Furthermore, protein-containing products often include carbohydrates and minerals as well as proteins from multiple sources. The interactions between the different components further impact how and why fouling occurs.

The industrial consortium on “Proteins on steel: science-based solutions for fouling in the food industry” aims to combine the practical and the scientific sides of the issue, to enable the development of optimal solutions and predictive models. This is quite a unique approach. As I mentioned, production facilities themselves are using methods developed over time, with trial-and-error. Universities and research facilities, on the other hand, explore the topic from the wholly scientific perspective. They may study adhesion of proteins on steel, for example, but using purified water and pure proteins. This research reveals important insight, but it doesn’t reflect the realities of the production environment, and thus the complexity of the fouling situation.

RF: What is the role of the industrial consortium?

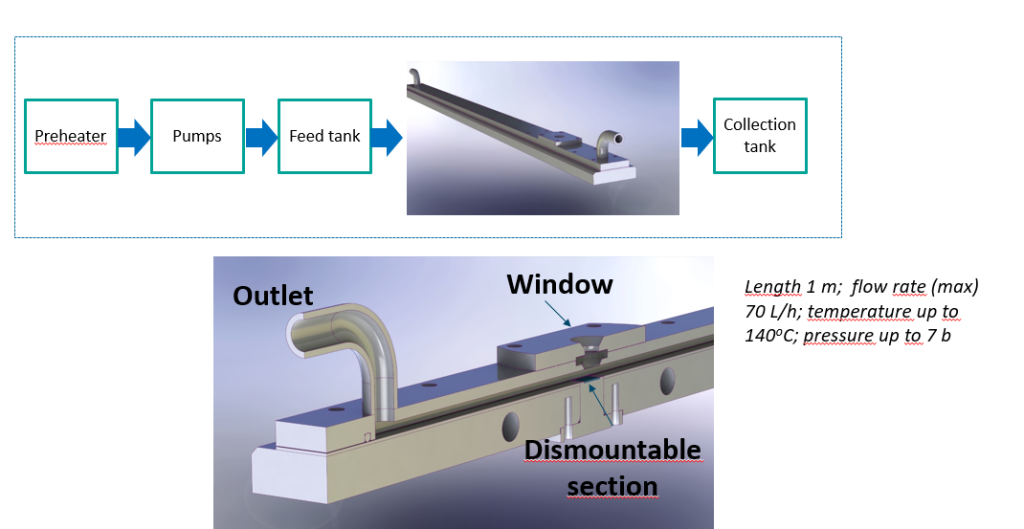

HT: The consortium is using scientific methods to look at what is happening under relevant industrial conditions, at the molecular level. NIZO designed a device that enables us to test the real materials used in production equipment, under a broad range of conditions.

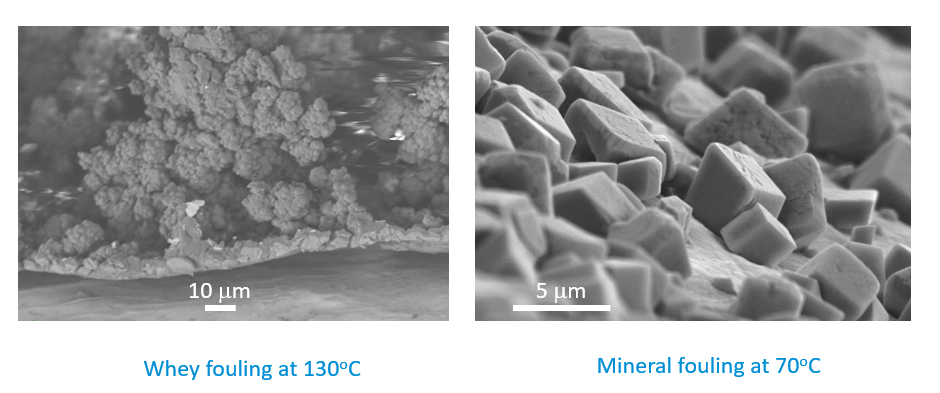

We can insert a sample of the specific surface material (steel or coating), and then run the actual product formulation through the device. We use real process conditions, including temperature, flow rate, etc. to mimic the specific processing stage. For example, we can bring temperatures to around 130oC to mimic UHT treatment. Then, we remove the surface sample, and study the fouling deposits on it using a range of spectroscopic and microscopic techniques.

We have found, for example, that fouling generally is not a single layer: there are usually multiple layers, typically starting with a mineral layer. We also discovered that mineral fouling can happen at much lower temperatures than protein fouling. For example, calcium salts in water can already become insoluble at 70°C, causing them to adhere to the steel. This first mineral layer can then create an even greater surface for protein fouling to attach. Using techniques such as liquid chromatography and mass-spectrometry, we have also found that only specific proteins in a protein mixture will contribute to the fouling.

Insights like this open up several possibilities for optimisation strategies: finding a water source with less calcium, or selecting a specific coating for the steel that reduces calcium adherence, for example.

RF: What role can modelling play in reducing fouling?

HT: Once we understand the mechanisms that are causing fouling in a specific situation, we can develop models to optimise the processing conditions, and ideally reduce downtime, cleaning costs, etc. So, whether a food producer wants to improve an existing process or is adding a new product or even new equipment, predictive modelling could provide science-based insight into which surface coatings are best for which complex protein mixtures, or what temperatures and flow rates will minimise the fouling.

This will be particularly helpful with the increased use of plant proteins. Plant proteins create new challenges for manufacturers, because there are so many different types of proteins, and much less is known about them than, say, about dairy proteins. But the fouling testing device is “protein-agnostic”, meaning the source of the protein doesn’t make a difference. So rather than starting from the position of “doing things the way they have always been done”, and then adapting the processes by trial and error, manufacturers can make more informed decisions based on the real and relevant behaviour of their specific (plant) product.

- High Throughput Screening

- Confocal Microscopy

Related terms

© NIZO 2025 | Sitemap - Privacy Statement - Cookie Statement - Terms & Conditions

Website by: Online Marketing Agency