Table of Contents

Creating new value from biomass sidestreams of existing processes makes sense for everyone, opening up new revenue and supply sources, while reducing waste and carbon footprint. The OLEAF4VALUE Consortium, led by Natac, is developing a complete valorisation system for olive leaf biomass that could have a big impact for food ingredient manufacturers. José Maria Pinilla, R&D Project Manager at Natac, and Guus Kortman, Scientist and Senior Project Manager Microbiomics at NIZO, explain.

What makes olive leaves a good candidate for biomass valorisation?

José Maria Pinilla: There is a stable and almost unlimited supply of olive leaf biomass, from the ever-growing olive oil production industry. Europe produces 4.1 million tons of olive leaves each year. This biomass has to be removed from olive groves and olive oil mills, and disposed of, generally through burning or as animal feed.

Currently, only around 0.2% of the olive leaf biomass is used for extracts, partly because it is very difficult to work with. However, there are interesting applications and significant market demand: but we need to find innovative ways to get the products to manufacturers, and ultimately, to end-users.

Why are olive leaf extracts interesting for food and supplement ingredient manufacturers?

Guus Kortman: Olive leaves contain a wealth of polyphenols, triterpenoids, essential oils, lipids and lignocellulose. The olive leaf biomass can be used to provide a reliable supply of new or improved bioactive compounds that could help food and supplement manufacturers meet increasing consumer demand for products offering health benefits. Some of the phytochemicals or combinations of compounds may have anti-inflammatory, antioxidant, prebiotic or antimicrobial effects. Oleuropein, for example, is one of the main phenolic compounds in olive leaves, and has anti-hypertensive properties.

What are the challenges of creating new value with olive leaf biomass?

JP: To begin with, the composition of all olive leaves is not equal: each batch, even leaf potentially, can contain different amounts and ratios of the various phytochemicals. We need to better understand what factors impact the biomass composition: whether the leaves come from pruning or from milling, the time of year, the conditions in which the tree is growing, etc. We have to match the composition profiles to the most suitable applications, and then analyse each batch to ensure it goes to the ‘right’ application. And we have to find ways to improve cost-effectiveness and sustainability.

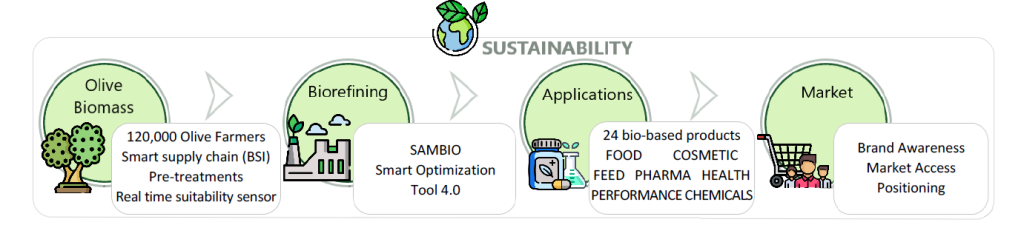

That is a lot to accomplish; it touches many industries and types of expertise: from supply chain development, to health benefit substantiation, to market exploration, and everything in between. That is why we set up the OLEAF4VALUE, an international consortium that brings together academic and industry partners, as well as olive growers. It’s a multi-million-euro project, which has received funding from the Bio-Based Industries Joint Undertaking under the European Union’s Horizon 2020 research and innovation programme. And we are using a unique, disruptive approach that we developed ourselves: SAMBIO. This stands for Smart Dynamic Multi-Valorisation-Route Biorefinery.

What is SAMBIO, and what makes it a disruptive approach?

JP: SAMBIO is an innovative cascade valorisation concept that takes into account the varying and specific composition of the biomass. It’s ‘dynamic’ because it is not always the same process. It is ‘smart’, because each process is adapted case-by-case based on the initial raw material composition. ‘Multivalorisation routes’ enable us to take as much value as possible for a certain batch of raw material. It’s an approach that hasn’t been seen before.

How does this help achieve the market potential for the olive leaf extracts?

JP: Within the consortium, we are aiming to develop tailor-made solutions for different industries, including food and supplements. We want to be able to deliver to them a higher-value, high-quality product with a high content of specific bioactive compounds, in a stable, sustainable way.

We also need to be able to sort the leaf biomass, and direct it towards the biorefinery route leading to the right application. One of our partners is working on a sensor that will enable olive leaf biomass to be analysed in real time for its suitability for the various applications. So each stream gets the most appropriate biomass, which is more cost-efficient and supports our zero waste goals.

Say, for example, we find that a certain combination of polyphenols and tripenoids has a synergistic anti-inflammatory effect. On the one hand, we want to ensure that the ingredient manufacturers receive extracts with that mix. On the other, we want to make sure that biomass with that mix gets funnelled to those ingredient manufacturers.

How are you ensuring the extracts offer the quality that manufacturers need?

GK: The consortium is using innovative technologies, such as molecularly imprinted polymers, enzymatic biotransformation, and encapsulation processes to create new, ‘second generation’ products that better match what manufacturers need. Triterpenoids, for example, are not well absorbed by the body because they have low water solubility and tissue permeability. We may be able to solve this using different encapsulation models, or by linking them with fatty acids or other molecules. But we need to prove that these modifications and novel products deliver the bioactivity and bioavailability and, ultimately, the desired health benefits.

What methods are you using to substantiate the health benefits?

GK: The work plan for substantiating health benefits includes both in vivo and in vitro studies. Martin Luther University, in Germany, is carrying out in vivo tests with the widely used Caenorhabditis elegans (C. elegans) models to look at antioxidant activity, and how the extracts modulate the lifespan and health of the C. elegans nematodes.

At NIZO, we are carrying out the in vitro studies, using cell cultures to see the impact of the extracts on intestinal epithelial cells and on immune cells. But we are also looking at how the gut microbiota reacts to the extracts. The polyphenols and some of the xylo-oligosaccharides, for example, may act as prebiotics, which could impact microbiota composition and metabolism. Using our MicroColon model, we can mimic the luminal contents of the large intestine and simulate the effect of the extracts on microbial composition and metabolic signature. Then, we carry out shotgun metagenomics and transcriptomics to analyse microbial gene expression, and evaluate the effect of the fermented products or metabolites produced in MicroColon in the cell culture models. We can also ‘spike’ the MicroColon model with the intestinal pathogen Clostridioides difficile, to gain insight into the potential antimicrobial effect of the extracts.

What is the current status of the consortium project, and what’s next?

JP: We have completed the first year of the three-year project. We have begun characterising the olive leaves from around Europe. We have also received about 10 lab-scale prototypes of bio-products, including the first encapsulations, molecularly imprinted polymers (MIPs) synthesis, and enzymatic biotransformations. Now we need to upscale these to “demo” scale, which, depending on the compound, could be tens to hundreds of kilos of product. We have also started some in vitro testing with NIZO, which will help us screen for the most promising products. There is still a lot to do, but it is progressing!

Related cases

Related blogs

© NIZO 2025 | Sitemap - Privacy Statement - Cookie Statement - Terms & Conditions

Website by: Online Marketing Agency