René Floris: What is computer modelling?

Kevin van Koerten: A computer model is a mathematical description of a system that can be used to accurately simulate how that system operates. It is a way to quantify and apply knowledge and expertise to improve a product or process in a time- and cost-efficient manner. You can make changes to the system in the model and see what the impact on the output will be without having to interrupt production. And you can run through thousands of different choices in seconds, using powerful mathematical tools to find the optimal set up for your system without all the production losses and waste associated with trial-and-error.

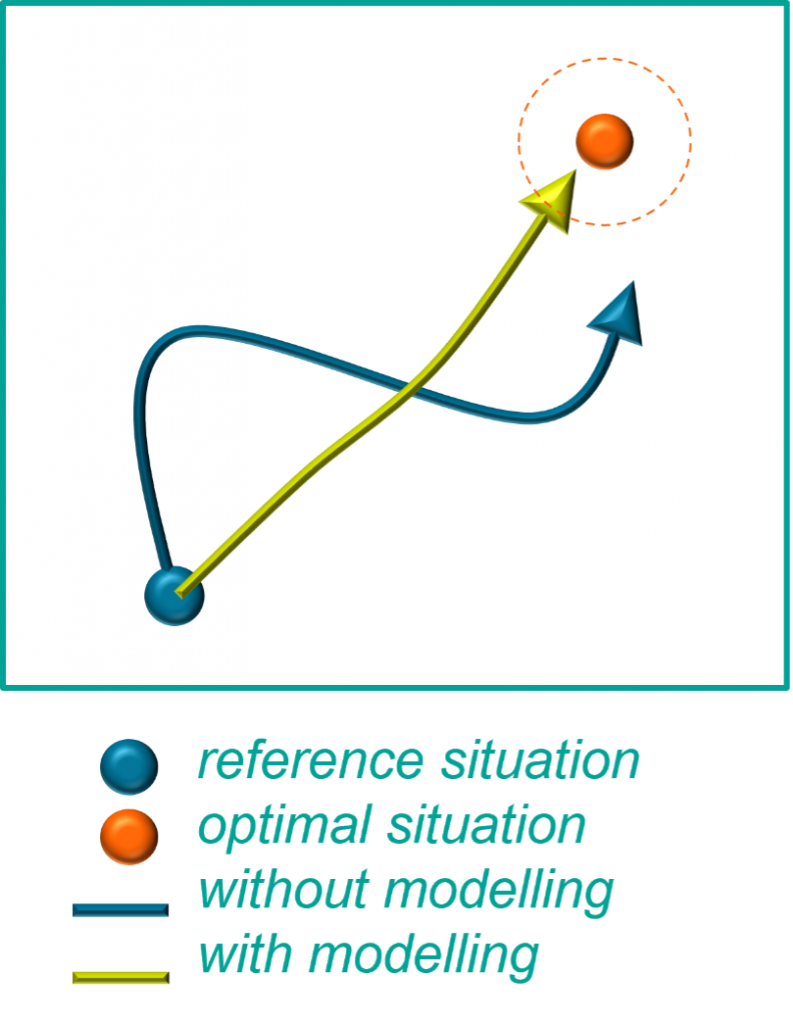

Process modelling provides a time- and cost-efficient route to the optimal production set-up, avoiding the delays and waste associated with trial-and-error approaches.

RF: How can computer modelling be applied to food manufacturing?

KvK: Modelling has many applications in the food industry. Troubleshooting is an obvious one, using a model of your entire process – or even just a specific stage – to locate, identify and solve production issues quickly.

You can also use it to optimise processes, either before you deploy a new process or to improve the performance of an existing one. That could be to reduce power and resource consumption, increase production capacity without investing in new equipment, or to improve the overall quality of the product or process. At NIZO, whenever we do pilot production for a customer, we always start by running a model of, at least, the key steps in the planned process to optimise the set up for the customer’s needs and ensure we run our pilot plant efficiently.

In addition, to this process-focused modelling, you can also apply models for microbial growth and inactivation to give you a head start in food safety. You could easily replace two days of lab experiments with just a few seconds of modelling.

RF: What kind of process steps can be modelled?

KvK: Practically any food production process step can be optimised through computer modelling. But among the most commonly modelled steps are evaporation, membrane filtration, heat treatments and spray drying.

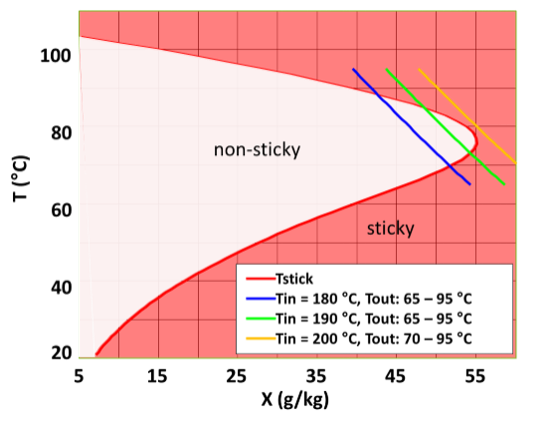

For example, powders are a massive part of the ingredient industry. The spray dryers that produce them handle tonnes of material each hour, so any gain in spray dryer output can have a massive impact on a powder manufacturer’s bottom line. Modelling lets you predict the capacity of the spray dryer as well as the moisture content and surface stickiness of the resulting powder. With the right model, you can optimise the spray dryer set up to deliver the maximum throughput while also minimising stickiness and related fouling and meeting the required product specifications.

Typical output of a spray dryer model, taking into account capacity, final powder moisture content and powder stickiness.

RF: Can I buy process models “off the shelf” or do they have to be built from scratch each time?

KvK: Standard models of various steps used in food production processes do exist. But for a model to deliver useful results, it must describe your actual process (step) as closely as possible. So, these models need to be carefully chosen and tailored to your set up. And that takes expert insight.

Effective modelling is not just a case of having the fastest computers. There is a saying in the IT world, “Garbage in equals garbage out”. You need a real understanding of food and its production processes to know what to model and how best to model it, otherwise your models can take too much time and resources to run, or you end up with answers that are mathematically correct but of no value in a real production set up.

RF: How does that expert insight inform modelling?

Let’s look at heat treatment as an example. The goal here is to kill of microbes and ensure food safety while minimising the impact to the taste, texture and look of the food. The figure of merit here is F0 or the microbe killing power relative to the killing power of 1 minute at 121 °C. A simple model would look at all microbes and / or spores that could be present in the product which could lead to a very extreme heat treatment prediction – potentially denaturing the proteins in the product and causing issues with product quality and fouling in the production line. However, if you understand which microbes can cause problems in your product, you can incorporate their specific kinetics into the model to find a less extreme heat treatment that still ensures food safety.

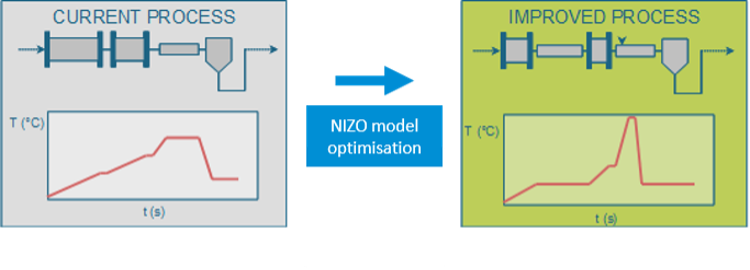

Similarly, applying knowledge of the thermal denaturation of proteins to models can allow you to improve the design of production processes as a whole, and thus significantly improve production. In one example we looked at, protein denaturation during the production of a powdered product was causing severe fouling. Through computer modelling that built on our knowledge of protein denaturation, we were able to ensure that any denaturation – and thus fouling – occurred in the wider pipes in the production set up rather than delicate evaporation equipment. This increased runtimes by a factor of 6 and increased capacity by 80% – all while keeping the F0 the same as the original process. Doing this through physical trial and error would have taken a year or so. With modelling, it took one week.

Overview of simulation results before and after model-based optimisation of a heat-treatment process that improved capacity by 80% while maintaining the same F0.

RF: I see a lot of talk about “digital twins”. What are they and are they relevant to food production?

KvK: Digital twin is certainly a buzzword in process modelling right know – across many industries. But it is actually just a new name for a concept that has been around for quite a while. A digital twin is a continuous computer model that is periodically updated and calibrated with real process data to ensure it stays current. This is effectively what we have been doing with our spray dryer models for the last forty years – now they would be called a digital twin.