Nestlé and NIZO have developed a new process for an Edam cheese with reduced fat, which supports Nestlé’s goals to reduce saturated fat in frozen pizza. The cheese has 30% less fat than the full-fat version, but offers all the flavour, melting behaviour and shreddability, without requiring special ingredients or equipment by the cheese producer.

Frozen pizza is a multi-billion-dollar industry globally, and growing. Nestlé S.A. is amongst the top players, with brands including DiGiorno, California Pizza Kitchen, Tombstone and Jacks in the USA, and Wagner and Buitoni in Europe. As part of its commitment to nutrition, health and wellness, Nestlé S.A. looks for new ways to meet consumer demand for ‘healthier’ products, including its frozen pizzas, by reducing fat, sugar and salt.

Reducing saturated fat in frozen pizza

Cheese is the major driver of saturated fat in frozen pizza, and Edam cheese is often used as a topping for these products. Switching from a full-fat to an Edam with less fat thus offered an excellent opportunity for Nestlé to improve the healthiness of its frozen pizza range.

The fat-reduced Edam cheeses available on the market, however, did not offer the characteristics needed for a high-quality frozen pizza. Their crumbly texture prevented easy shredding, and when heated, they didn’t melt smoothly, they browned too much, were less aromatic, and had a dry mouthfeel.

Strict requirements for a fat-reduced Edam cheese

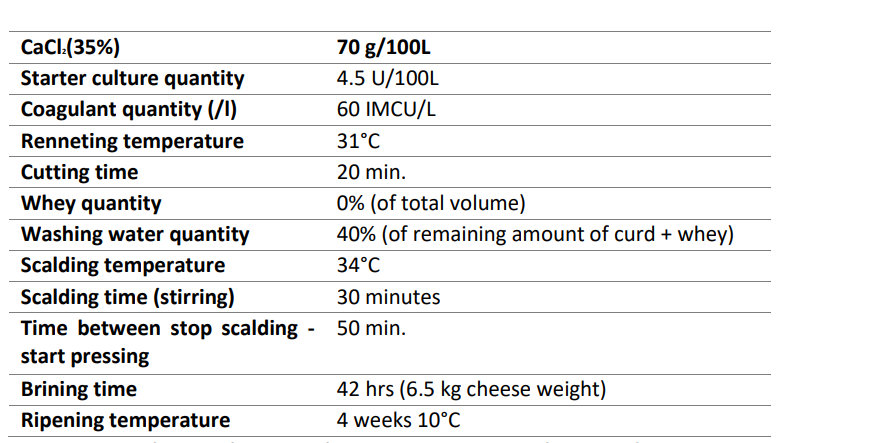

The requirements for the new cheese were strict. It had to offer both good shreddability and meltability, with low browning when heated. It also had to conform with the German KäseVerordnung regulations on cheese, which prohibit the use of certain additives and heat treatments, for example. The process (Table 1) had to be easily transferable to Nestlé’s cheese suppliers, without requiring additional costs, ingredients or equipment. “The primary requirement, however, was taste, of course, because in the end that is the most important factor for the consumer,” says Praveen Upreti.

Balancing fat, moisture and protein

NIZO began by inventorying potential strategies within these boundaries. “We focussed on raising the moisture-to-protein ratio of the fat-reduced cheese to that of full-fat cheese, and increasing proteolysis, (the breakdown of the proteins). A full-fat Edam is about 23% fat in total weight, whereas a low-fat version is about 15% fat in total weight. In the latter, the fat is replaced by water and proteins. But the balance of these is critical. If you have too much protein, for instance, it can cause difficulty with texture and melting behaviour,” explains Durita Allersma, Project Manager at NIZO food research.

During the project, which ran from February to December 2021, NIZO and Nestlé’s application team in Germany collaborated closely. NIZO would prepare and age a series of cheeses, which would be sent for testing on sensory and functional aspects by Cynthia Wagner and Klaus Riebel, the Nestlé application team. The two groups would then meet to discuss the results, after which NIZO would develop another set of cheeses to be tested. In total, NIZO produced three series of six cheeses.

Same taste, texture and behaviour, with less fat

“We successfully developed a fat-reduced cheese-making process that increased the moisture/protein ratio to that of full-fat cheese. This improved not only melting behaviour, but also creaminess and shreddability. Using a relatively high dosage of a high-proteolytic-activity rennet further enhanced meltability. We identified a mixed-strain, mesophilic culture that provided the best flavour, while supporting the functional characteristics needed for the frozen pizza application. Our results also showed that pre-ripening and homogenisation of a portion of the milk did not contribute to better melting or creaminess, eliminating the need for these steps in the production process,” says Wim Engels, Senior Project Manager at NIZO food research.

“The resulting fat-reduced cheese is a near-equivalent to full-fat Edam. The flavour is essentially the same, while the behaviour of the cheese allows us to deliver a pizza with less fat, without compromising on texture, visual presentation, etc. Furthermore, the culture and rennet are both commercially available, and the entire process requires no unit operations that are not already available at the cheese production facilities. We will be visiting our vendors to share this new process openly, and look forward to transitioning to the fat-reduced cheese for our pizza ranges in Europe,” says Praveen Upreti.

Related cases

Related blogs

© NIZO 2025 | Sitemap - Privacy Statement - Cookie Statement - Terms & Conditions

Website by: Online Marketing Agency